Piano & Player Piano

Pianos are complex mechanical devices and with use and time, deteriorate to a point where they may

require more than what can be achieved with a home visit by a technician. This can range from simply

replacing worn felts or broken springs to complete rebuilding or even re-manufacturing. Often the

piano action (mechanism) can be removed from the piano for restoration work or it might be necessary

to move the entire instrument.

Although it can be difficult to recoup money spent on older pianos, people commonly choose to have a piano rebuilt for the following reasons:

Although it can be difficult to recoup money spent on older pianos, people commonly choose to have a piano rebuilt for the following reasons:

- The piano has sentimental value.

- The piano was originally of high quality and the cost of rebuilding is still lower than purchasing a new piano of similar quality. Remember that new upright pianos in the $4-6k range are considered "entry level" and are generally not of high quality!

- The piano has an interesting case and/or exquisite veneers that simply aren't available on modern pianos.

- The owner enjoys the tone and touch of their piano but wants it to play like new.

Spraying case parts in the spray booth

Pianos awaiting restoration

Before and after photos of finish restoration

Freshly strung piano back

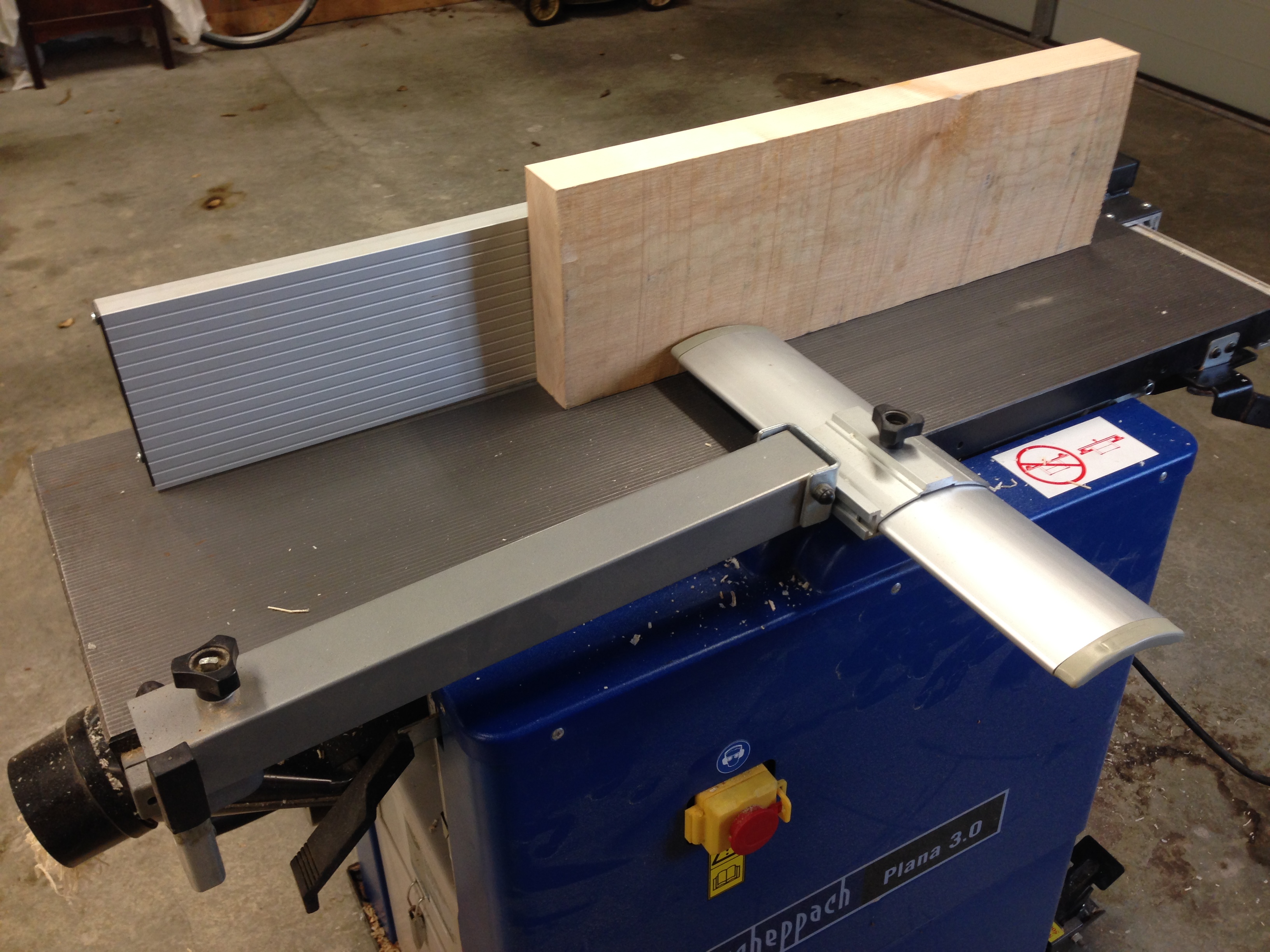

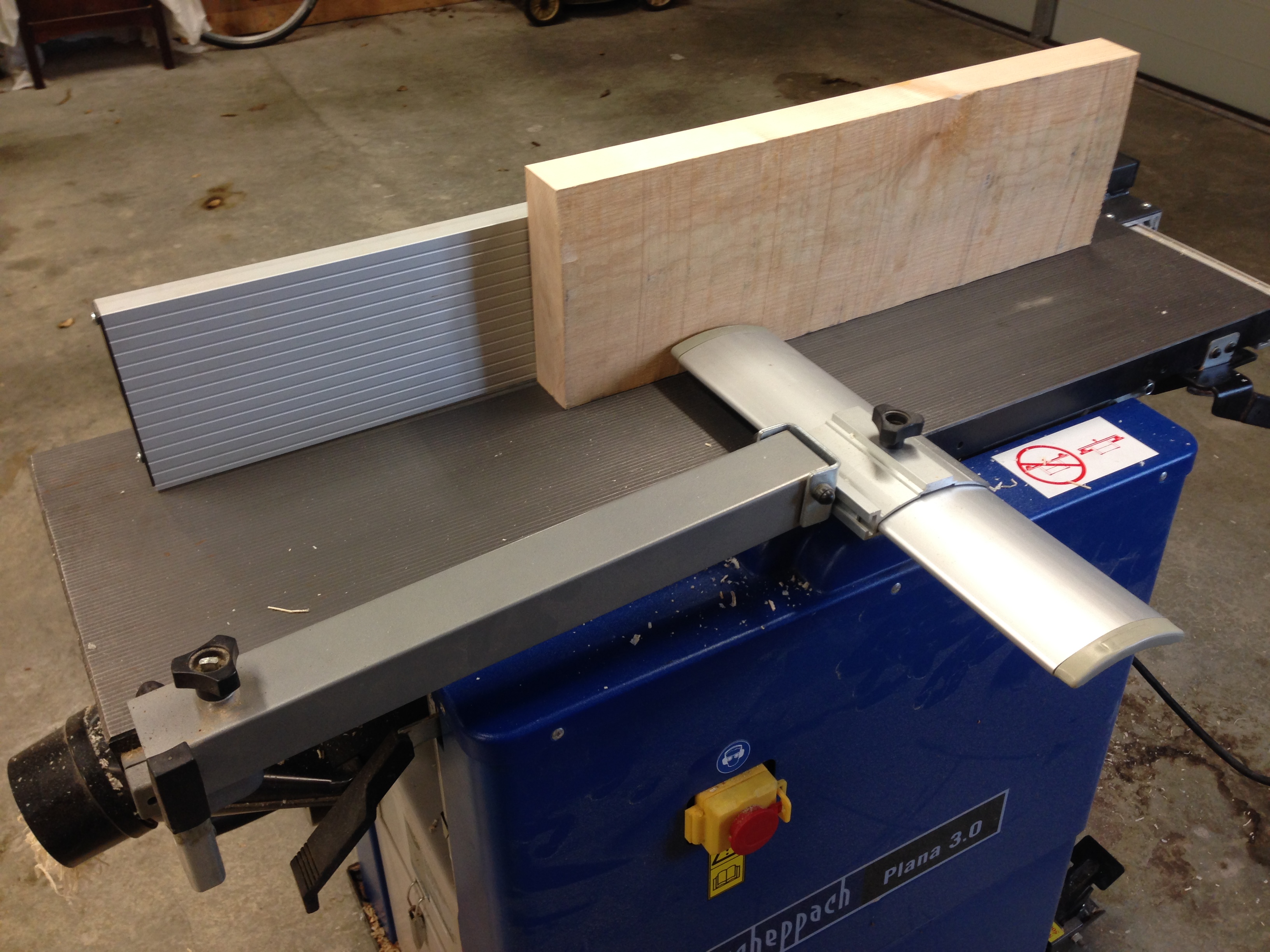

Machining rock maple for piano parts

New damper felts. The bass dampers were redesigned to work more efficiently -

notice the old example on the left

Gluing Ronsen grand hammers onto new shanks